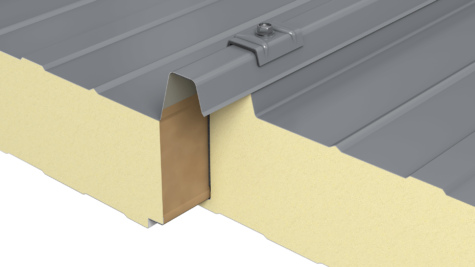

Brucha’s Roof Panel DP provides excellent span capabilities and thermal values up to R-43. The classic high rib design provides an architectural highlight for any application. This panel is suitable for both single and double sloped roofs and can be used on pitches of ⅜:12 or greater and does not require seaming. Our DP Roof Panel features a triple sealed system and offers optimum protection against condensation. It also fully integrates with our rated Fire Protection Roof panels (DP-F) without adapter profiles or trims/flashings. The system comes complete with painted saddle clips for optimum sealing and panel spans and may be used over steel or wood purlins. In line with EN 14509 39 3/8 in (1000 mm) 26 dB at 2 3/8″ / 3 1/8″ (60/80 mm), 27 dB from 3 15/16″ (100 mm) core thickness max.40ft (45ft by special arrangement) 194° F / 90° C FM 4471 Class 1 Fire Rating of Insulated Wall or Wall and Roof/Ceiling Panels, Interior Finish Materials or Coatings, and Exterior Wall Systems 1 9/16 in (40 mm) – 6 5/16 in (160 mm)High Static Load Capacity Roof Panel

BRUCHAPaneel® Roof DP

Composition & Attributes

exterior

interior

insulation core

panel connection

testing & certifications

At a Glance

BRUCHAPaneel® Roof DP

Samples + Support

Samples

Want to see our panels up close? We have samples! Contact us and we will get one shipped to you!

Support

Need help? From theoretical questions about our panels to practical questions on how to install panels correctly, BRUCHA has you covered.