Solidboard® is an innovative solution for food processing facilities requiring high levels of sanitation and resistance to damage from chemical washdowns where standard paint finishes are not up to the task. Solidboard® is most often used on interior liner panels and partitions. Solidboard® is a fiberglass reinforced facing material that can be bonded to our standard PIR WP panels with or without steel facings on one or both sides. Our manufacturing flexibility helps our customers select the most cost effective product for each application. COMPOSITION AND ATTRIBUTES

Unit Value approx. Density lbs/in3 0.047 – 0.0542 Tensile strength (fabric-reinforced) psi 13,100 – 21,800 Elonigation at break % 1 – 2 Flexural strength psi 18,900 – 24,700 Compressive strength psi 21,800 – 26,100 Impact resistance ft-lbs/in2 19 – 29 E-module (bending test) psi 1,015,000 – 1,450,000 Barcol hardness Mg 40 – 60 Thermal properties Unit Value approx. Application temperature °F -22 to +176 Application limit temperature (temporary) °F -58 to +266 Thermal expansion coefficient °F-1 16-22×10-6 Vapor diffusion resistance coefficient µ 60,000 – 90,000 Thermal conductivity coefficient BTU/hr· ft· °F 0.12 Heat transition coefficient BTU/hr· ft2· °F 0.97 In line with EN 14509 max. 40 ft. (45 ft. by special arrangement) 194° F / 90° CHygienic, Easy to Clean Wall Panels

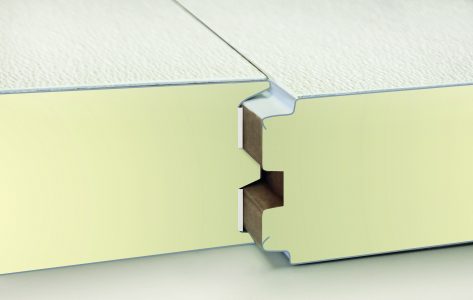

Solidboard® Panel

areas of application

![]()

product options

for renovation purposes on various substructures, such as masonry, tiles, panels, etc.

factory laminated wall or facade panels for indoor applications

– foamed, shear resistant bond with the covers

– core thickness 3-5/32″, 3 15/16″ and 5-1/2″ (80, 100, 140 mm) other thicknesses upon request)

– max. panel length – 19.7 ft

– Insulation core made of EPS100/150, flame-retardant, limited to cover panels in a shear-resistant manner

– Available in insulation thicknesses from 13/16 to 11-13/16″.

– Panel lengths between 6.5 and 39.8 ft.

– Areas of application: interior finishing of processing and cold-storage roomsmechanical properties

thermal properties

At a Glance

Solidboard® Panel

Samples + Support

Samples

Want to see our panels up close? We have samples! Contact us and we will get one shipped to you!

Support

Need help? From theoretical questions about our panels to practical questions on how to install panels correctly, BRUCHA has you covered.