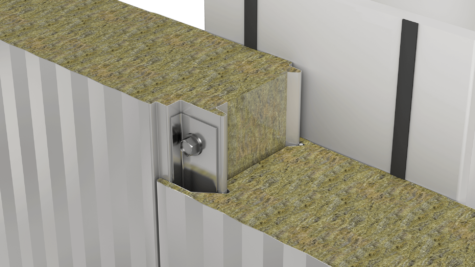

Brucha’s FP-F (Façade Panel – Fire Rated) is our concealed fastened façade panel with a non-combustible mineral wool core. These versatile panels can be installed either vertically or horizontally and offer protection against the elements by providing all four control layers (air, vapor, water and thermal) along with fire protection in a single component. The unique tongue and groove sidejoint features a bullnose along one edge allowing the use of concealed fasteners while providing a seamless appearance. Brucha’s standard oversized compression clip allows for superior panel spans, allowing greater flexibility in the design of structural supports. Our factory installed protective film at the sidejoints protects the core from unwanted moisture. Available in six different profiles, one and two hour fire ratings and 10 different thicknesses depending on the required R-value, FP-F provides the options you need for just about any project. Coil-coated galvanized steel-faced panels with mineral wool core insulation In line with EN 14509 43 5/16 in (1100 mm) SPECIAL WIDTH approx. 32 dB (frequency-dependent) max.40ft (45ft by special arrangement) 194° F / 90° C FM 4880 Class 1 Fire Rating of Insulated Wall or Wall and Roof/Ceiling Panels, Interior Finish Materials or Coatings, and Exterior Wall Systems 2 3/8 in (60 mm) – 9 7/16 in (240 mm)Fire-Rated Façade Panel

BRUCHAPaneel® FP-F

Composition + Attributes

exterior

interior

insulation core

panel connection

testing & certifications

At a Glance

BRUCHAPaneel® FP-F

39 3/8 in (1000 mm)

Samples + Support

Samples

Want to see our panels up close? We have samples! Contact us and we will get one shipped to you!

Support

Need help? From theoretical questions about our panels to practical questions on how to install panels correctly, BRUCHA has you covered.